We provide corrosion-resistant alloy seamless pipes and welded pipes that meet NPS standard specifications, and also support customized non-standard pipes. We can produce thick-walled tubes, thin-walled tubes, straight tubes, special-shaped tubes, heat exchanger tubes, condenser tubes and instrument tubes according to customer requirements. Additional machining options include drilling, boring, milling and threading.

904L (UNS NO8904, EN 1.4539), also known as super stainless steel, is a low-carbon, high-alloy austenitic stainless steel designed for environments operating under extreme corrosive conditions. It has excellent corrosion resistance, especially in dilute sulfuric acid. It is also highly resistant to chloride crevice corrosion and stress corrosion cracking, is not prone to corrosion and cracks, and has excellent processability and reliability. Weldability makes it suitable for a variety of applications, including pressure vessels.

The excellent corrosion resistance of 904L is mainly due to its low carbon content (maximum 0.020%) and high content of alloying elements such as chromium, nickel, molybdenum and copper. These characteristics allow 904L to perform well in a variety of corrosive environments. Specifically:

904L does not undergo carbide precipitation during general heat treatment and welding processes, thus eliminating the risk of intergranular corrosion. The high content of chromium, nickel, molybdenum and copper elements allows 904L to be passivated even in reducing environments (such as sulfuric acid and formic acid). The corrosion rate of 904L in the active state is relatively low and it shows good corrosion resistance. 904L has excellent corrosion resistance in sulfuric acid and phosphoric acid within a certain concentration range. Among various phosphoric acids, 904L has better corrosion resistance than ordinary stainless steel. In hydrochloric acid, 904L can be used at lower concentrations (1-2%) and has better corrosion resistance. In chloride solutions, 904L exhibits good resistance to crevice corrosion. The high nickel content of 904L reduces sensitization, making it more resistant to stress corrosion at high temperatures. The high nickel content makes 904L highly resistant to stress corrosion cracking in chloride solutions, concentrated hydroxide solutions and hydrogen sulfide-rich environments.

Petroleum and petrochemical equipment: 904L is often used in reactors in petrochemical equipment to resist highly corrosive environments.

Sulfuric acid storage and transportation equipment: For example, 904L is often used to manufacture sulfuric acid storage tanks, heat exchangers and other equipment to ensure the safe storage and transportation of sulfuric acid.

Power plant flue gas desulfurization equipment: 904L is widely used in power plant flue gas desulfurization equipment, including the tower body, flue, baffle plate, internal parts and spray system of the absorption tower to cope with corrosive flue gas environment.

Organic acid treatment system: 904L is used to manufacture equipment such as scrubbers and fans to treat media containing organic acids.

Seawater treatment equipment: 904L is widely used in seawater treatment equipment, including seawater heat exchangers, to ensure that the equipment is not corroded in seawater environments.

Paper industry equipment: 904L can be used to manufacture equipment related to the paper industry to cope with environments containing chemicals and acidic media.

Sulfuric acid and nitric acid equipment: 904L is often used in the manufacture of sulfuric acid and nitric acid equipment to maintain the integrity and performance of the equipment.

Acid-making and pharmaceutical industries: 904L can be used in equipment in the acid-making and pharmaceutical industries to ensure the purity of the medium and the reliability of the equipment.

Pressure vessels: 904L can be used to manufacture various types of pressure vessels to meet the requirements of high pressure and corrosive media.

Food equipment: The applications of 904L in the food industry include the manufacture of soy sauce cans, sprinklers, salt shakers and other food equipment to ensure that no contamination is caused when the equipment comes into contact with food.

Supply style

Plates, bars, pipes, pipe fittings, fasteners, flanges, etc. can be processed according to drawings, please contact us.

Send Us Your Quotation By Email Can Get A Discount, Contact Us To Get Price List!

Wuxi Xinshanhu Steel Co., Ltd. is an eleven-year-old Chinese alloy manufacturer with rich production experience, well-trained workers and excellent engineers. Our factory has a mature production system and multiple steel production lines. Including Cold-rolled flat cutting machine, Hot-rolled flat cutting machine; High-speed flat cutting machine; Precision high-speed slitting machine, Ultra high pressure water jet cutting machine; Sheet fiber laser cutting machine; Thin-walled cylinder longitudinal seam automatic welding machine and Machine shop. Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc. The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q1. Where is your factory?

A1: Our company’s processing center is located in Wuxi, Jiangsu, China. It is well equipped with kinds of machines, such as laser cutting machine, mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products?

A2: Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc.The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q3. How do you control quality?

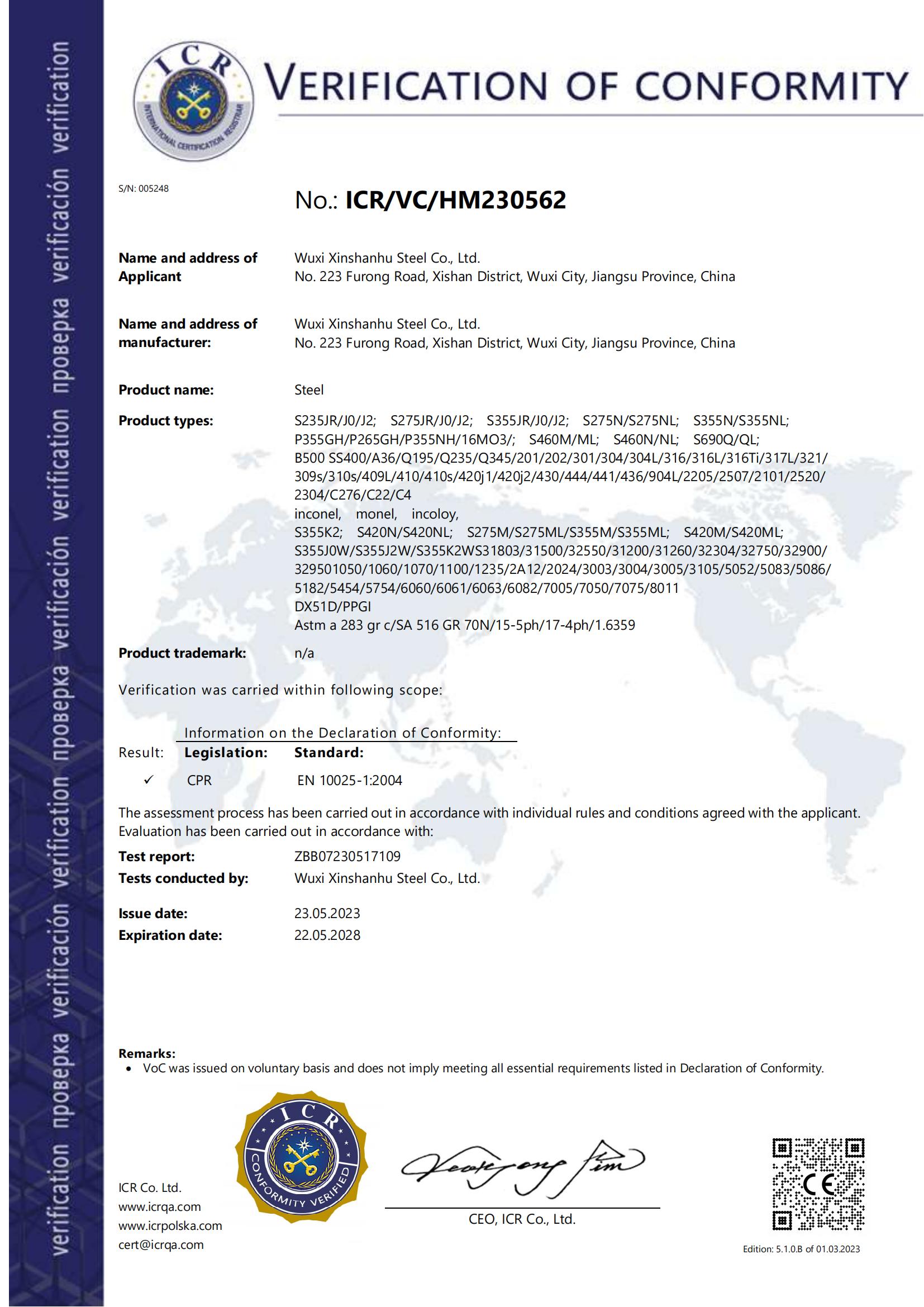

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company?

A4: We have many professionals, technical personnel, more competitive prices, and best after-sales service than other alloy companies.

Q5. How many countries have you already exported to?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan, India, etc.

Q6. Do you provide samples? is it free or extra?

A6: Yes, we could offer the sample for free charge but do not pay the cost of freight.