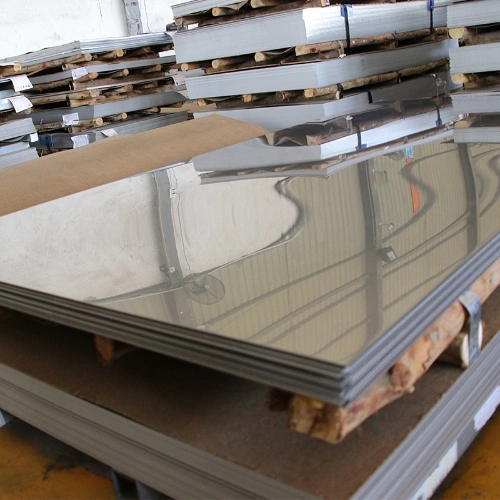

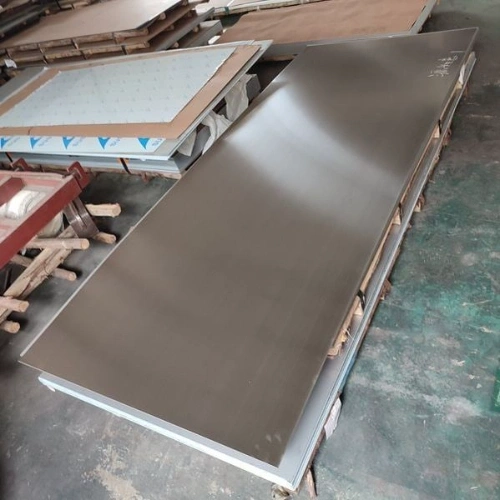

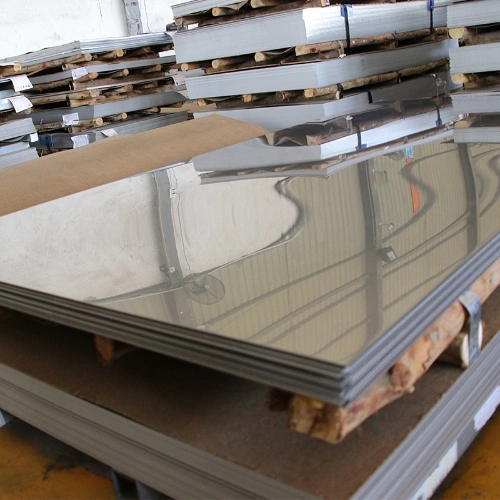

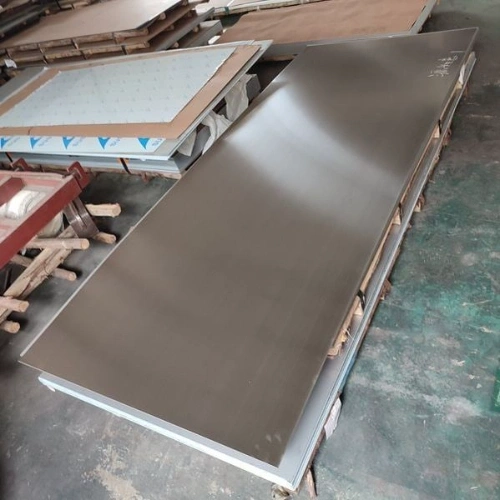

We provide corrosion-resistant alloy plates with thicknesses of 0.3mm-20mm and have a large inventory of cold-rolled plates and hot-rolled plates. We support the sale of single whole plates and customize special shapes or patterns according to customer needs and drawings. Our factory's sheet processing capabilities include shearing, HD plasma cutting and bevel cutting, water jet cutting and laser cutting (thin sheet), guaranteeing the possibility of realizing square, rectangular, round, ring and strip or custom shaped sheets.

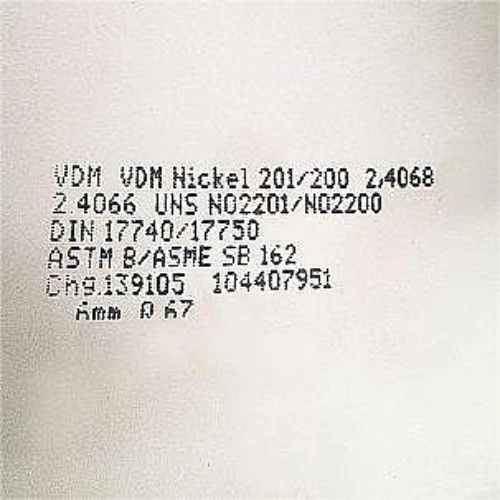

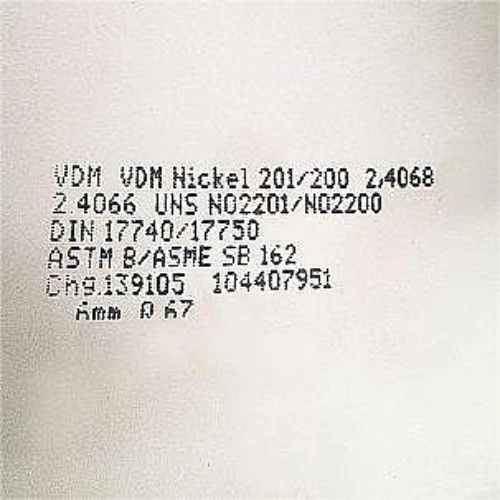

Pure nickel (Nickel 201, Nickel 200, ASTM B162, UNS N02201) is mostly used in reducing media and shows good corrosion resistance in many acidic and reductive corrosion environments. The outstanding feature is the corrosion resistance of alkaline media, such as caustic potassium, caustic soda, etc., which is widely used in the ion membrane caustic soda process. Nickel has also been successfully used in dry chlorine and hydrogen chloride at room temperature to 540°C. Can also be used in static hydrofluoric acid solutions. Nickel has good mechanical properties over a relatively wide temperature range, is easy to cold work (elongation is as high as 40 to 60%), and has properties similar to mild steel.

Nickel content: Nickel 200 and Nickel 201 are both highly pure nickel alloys with very similar nickel content, 99% and nearly 100% respectively.

Corrosion resistance: Both have excellent corrosion resistance and are highly resistant to various corrosive media, so they are widely used in the chemical industry and other corrosive environments.

Non-magnetic: Nickel 200 and Nickel 201 are both non-magnetic materials and therefore suitable for applications where magnetic interference needs to be avoided.

Nickel 200: Nickel 200 is a pure nickel alloy that usually does not contain other alloying elements and has a nickel content of close to 100%.

Nickel 201: Nickel 201 contains trace amounts of impurities such as copper, iron, manganese and silicon, and the nickel content is approximately 99%.

Nickel 200: Nickel 200 remains stable at extremely low temperatures, such as liquid nitrogen and liquid argon temperatures, making it suitable for ultra-low temperature applications.

Nickel 201: Although Nickel 201 has good corrosion resistance, it may not be as stable as Nickel 200 at very low temperatures.

Nickelcke Due to processing difficulties, it is difficult to roll particularly thin nickel strips, with conventional thicknesses above 0.2mm.

Nickel 200 and Nickel 201 are two pure nickel alloys that play crucial roles in many similar applications, with subtle differences in their chemical compositions leading to distinct characteristics in certain aspects.

Corrosion Resistance:

Both alloys exhibit outstanding corrosion resistance, particularly in acidic, alkaline, and saline environments, making them common choices for corrosive conditions in the chemical industry.

High-Temperature Performance:

Due to their high melting points and oxidation resistance, these alloys perform exceptionally well in high-temperature environments. They are often used in high-temperature heating elements, furnace components, and other applications requiring resistance to elevated temperatures.

Electrical Conductivity:

Nickel 200 and Nickel 201 are excellent electrical conductors, finding wide applications in the electronics industry and electrical engineering for manufacturing resistors, connectors, and cables.

Nuclear Industry:

Owing to their stability and resistance to radiation, both nickel alloys are extensively utilized in the nuclear industry, including the construction of nuclear reactors and other applications related to nuclear energy.

Chemical Processing:

Because of their corrosion resistance and chemical stability, Nickel 200 and Nickel 201 are commonly employed in chemical processing equipment, such as reactors and vessels.

Supply style

Plates, bars, pipes, pipe fittings, fasteners, flanges, etc. can be processed according to drawings, please contact us.

Send Us Your Quotation By Email Can Get A Discount, Contact Us To Get Price List!

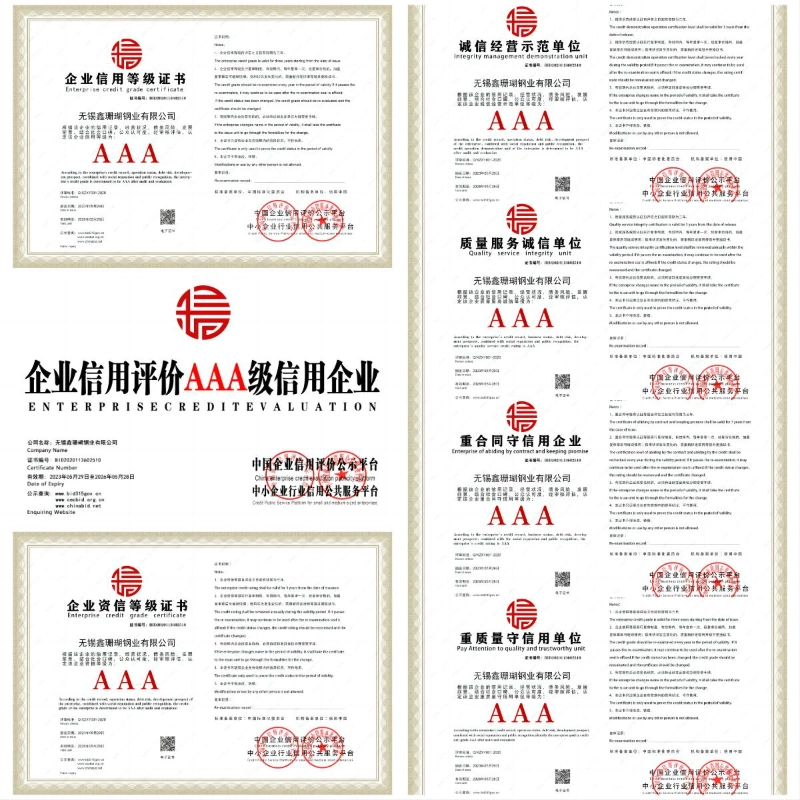

Wuxi Xinshanhu Steel Co., Ltd. is an eleven-year-old Chinese alloy manufacturer with rich production experience, well-trained workers and excellent engineers. Our factory has a mature production system and multiple steel production lines. Including Cold-rolled flat cutting machine, Hot-rolled flat cutting machine; High-speed flat cutting machine; Precision high-speed slitting machine, Ultra high pressure water jet cutting machine; Sheet fiber laser cutting machine; Thin-walled cylinder longitudinal seam automatic welding machine and Machine shop. Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc. The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q1. Where is your factory?

A1: Our company’s processing center is located in Wuxi, Jiangsu, China. It is well equipped with kinds of machines, such as laser cutting machine, mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products?

A2: Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc.The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

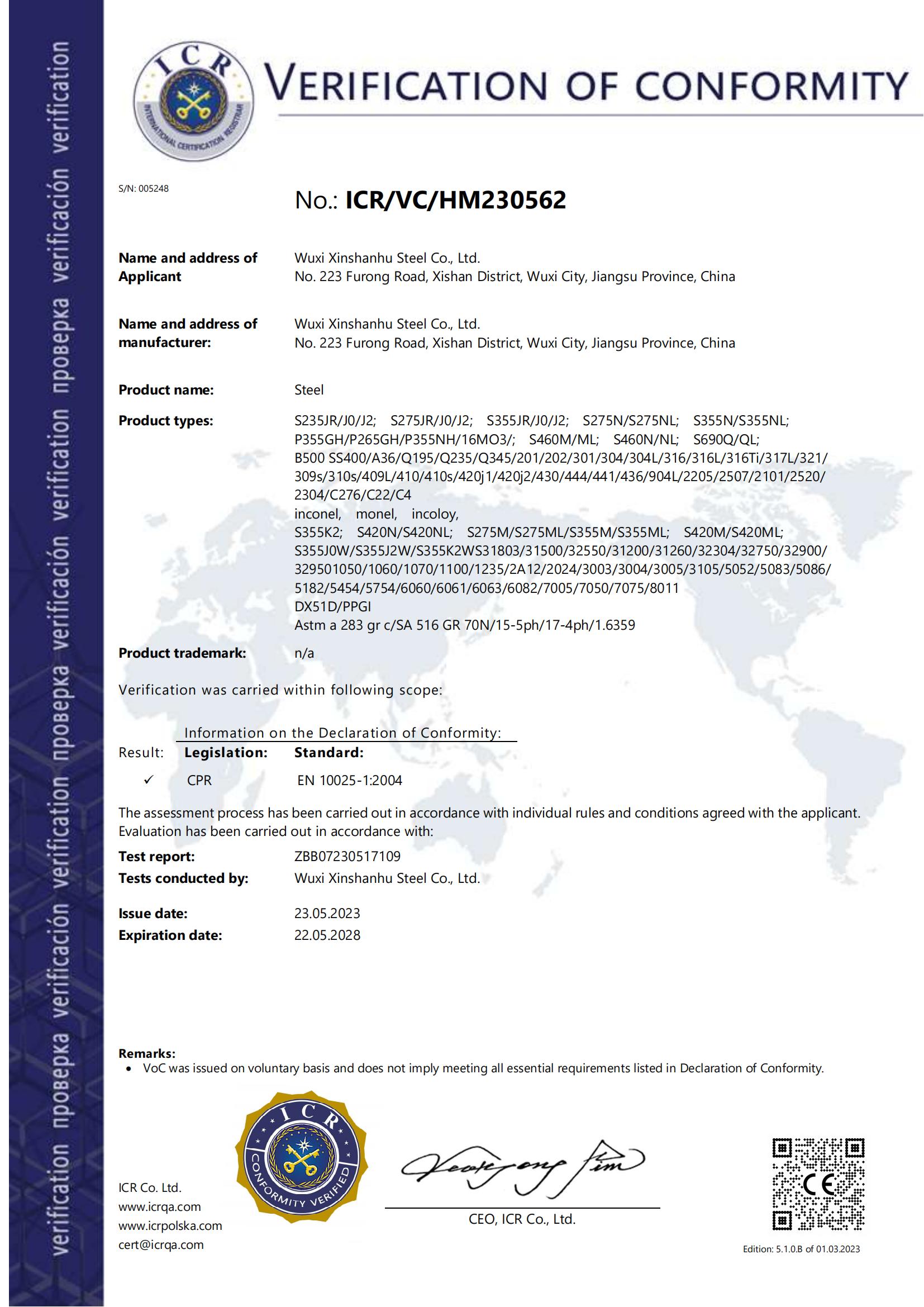

Q3. How do you control quality?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company?

A4: We have many professionals, technical personnel, more competitive prices, and best after-sales service than other alloy companies.

Q5. How many countries have you already exported to?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan, India, etc.

Q6. Do you provide samples? is it free or extra?

A6: Yes, we could offer the sample for free charge but do not pay the cost of freight.