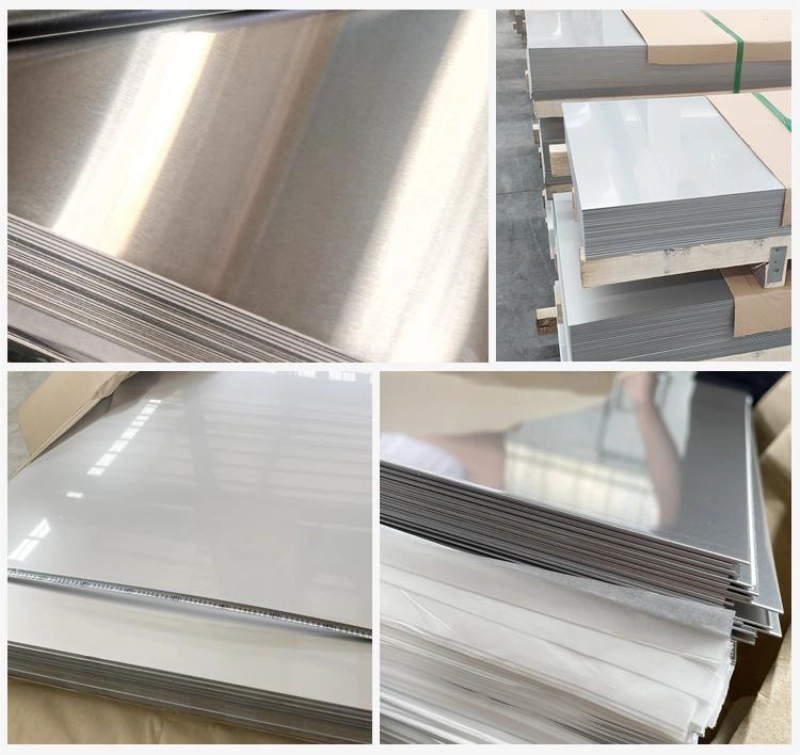

We provide corrosion-resistant alloy plates with thicknesses of 0.3mm-20mm and have a large inventory of cold-rolled plates and hot-rolled plates. We support the sale of single whole plates and customize special shapes or patterns according to customer needs and drawings. Our factory's sheet processing capabilities include shearing, HD plasma cutting and bevel cutting, water jet cutting and laser cutting (thin sheet), guaranteeing the possibility of realizing square, rectangular, round, ring and strip or custom shaped sheets.

UNS N07718, also known as Inconel 718 or 718 alloy, is a precipitation-hardening, high-temperature alloy primarily composed of Fe-Ni-Cr. It can be used for extended periods within a temperature range of -253°C to 650°C, with short-term usage up to 800°C. Below 650°C, it exhibits high strength, excellent toughness, and exceptional resistance to oxidation and corrosion in both high and low-temperature environments. It also boasts good processing and welding properties, as well as long-term structural stability.

The alloy can be effectively cooled with helium during vacuum consumable electrode remelting to reduce niobium element segregation. Using spray forming technology in component production can reduce costs and lead times, and superplastic forming can expand the production range.

Even complex parts can be easily manufactured using this age-hardening alloy. Its welding performance, especially resistance to post-weld cracking, is outstanding.

Inconel 718's ease of machinability, combined with its good tensile, fatigue, creep, and fracture strength, makes it widely applicable across various industries.

Inconel 718 exhibits exceptional resistance to stress corrosion cracking and pitting corrosion, regardless of whether it is exposed to high or low-temperature environments. It excels in oxidation resistance, especially at elevated temperatures.

When heating Inconel 718, it is crucial to ensure that the material and furnace operate within the correct temperature range.

The fuel used for heating must have an exceptionally low sulfur content. The material must be impeccably clean and free from oil, paint, grease, and workshop dust when loaded into the furnace.

For forging or open furnace annealing, the furnace environment should be slightly reducing, containing at least 2% carbon monoxide. There should be a slight positive pressure within the furnace to prevent air infiltration.

When Inconel 718 is heated in a reducing atmosphere, it may leave a thin, adherent black-green oxide film on the material's surface. In an oxidizing environment, a very stubborn black scale forms. Specific methods must be employed to ensure the formation of only a thin black-green film.

Inconel 718 is widely used in various demanding applications due to its high-temperature strength and excellent corrosion resistance at 700°C. It is easily processed and has been utilized in the manufacturing of components for aerospace, space exploration, and the petrochemical industry, including rings, blades, fasteners, and structural components. It is also used to create various parts for the petrochemical industry, allowing for mass production and excellent performance.

Gas turbines.

Liquid fuel rockets.

Cryogenic engineering.

Acidic environments.

Nuclear engineering.

Rings and sleeves in aircraft and land-based gas turbines.

Various forms of thin sheet metal components and low-temperature storage tanks.

Fasteners and instrument components, among others.

Supply style

Plates, bars, pipes, pipe fittings, fasteners, flanges, etc. can be processed according to drawings, please contact us.

Send Us Your Quotation By Email Can Get A Discount, Contact Us To Get Price List!

Wuxi Xinshanhu Steel Co., Ltd. is an eleven-year-old Chinese alloy manufacturer with rich production experience, well-trained workers and excellent engineers. Our factory has a mature production system and multiple steel production lines. Including Cold-rolled flat cutting machine, Hot-rolled flat cutting machine; High-speed flat cutting machine; Precision high-speed slitting machine, Ultra high pressure water jet cutting machine; Sheet fiber laser cutting machine; Thin-walled cylinder longitudinal seam automatic welding machine and Machine shop. Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc. The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q1. Where is your factory?

A1: Our company’s processing center is located in Wuxi, Jiangsu, China. It is well equipped with kinds of machines, such as laser cutting machine, mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products?

A2: Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc.The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q3. How do you control quality?

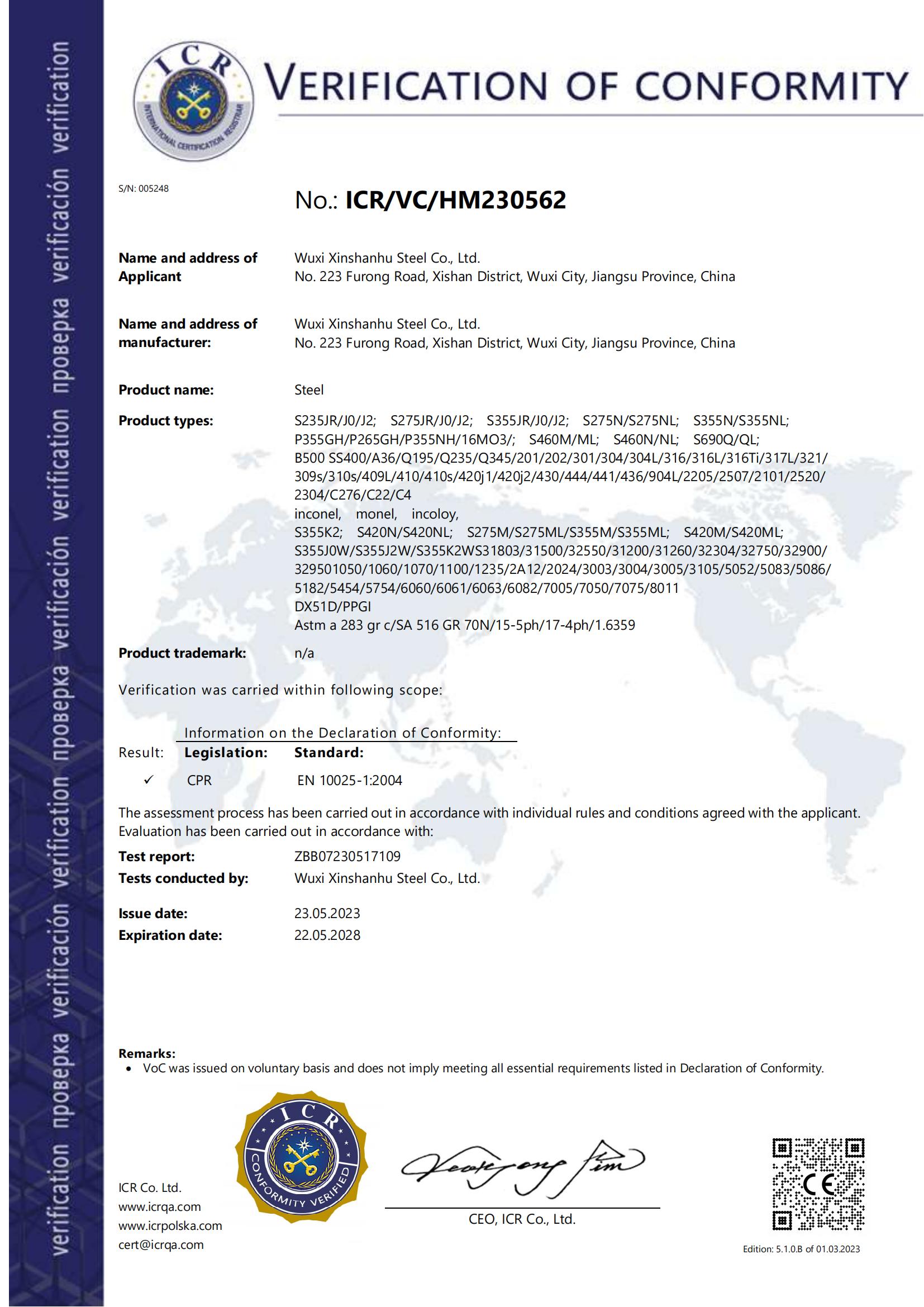

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company?

A4: We have many professionals, technical personnel, more competitive prices, and best after-sales service than other alloy companies.

Q5. How many countries have you already exported to?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan, India, etc.

Q6. Do you provide samples? is it free or extra?

A6: Yes, we could offer the sample for free charge but do not pay the cost of freight.