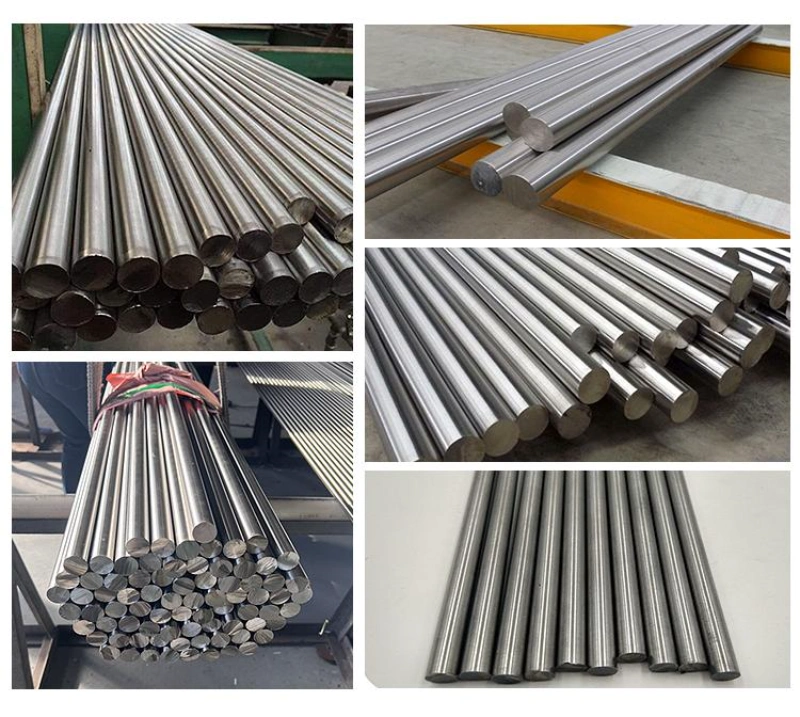

Our inventory includes a wide range of corrosion-resistant alloy bars spanning from 1/8" to 11" in diameter. You have the option to acquire bars in standard lengths, or we provide the convenience of custom cut-to-length services using our advanced bar processing equipment. Additionally, if you need further refinement, we extend machining services such as turning, grinding, polishing, milling, drilling, tapping, threading, and boring to meet your specific requirements.

Inconel 600, also known as N06600 alloy or 600 alloy, is a nickel-chromium-iron-based solid-solution strengthening alloy known for its excellent high-temperature corrosion resistance (resistance to acids and bases) and oxidation resistance. It exhibits superior cold and hot working properties as well as welding performance. Furthermore, it maintains satisfactory thermal strength and high ductility below 700°C. This alloy is designed for use in environments ranging from low temperatures to 1093°C. It demonstrates exceptional resistance to oxidation at 1093°C and has good resistance to carburization in reducing environments, except for those containing hydrogen sulfide, where the upper temperature limit is 535°C. It is highly effective in handling hydrogen chloride and chlorine gases at temperatures up to 538°C and 510°C, respectively. Inconel 600 also offers excellent resistance to corrosion from nitrogen, hydrogen, and carburization, making it suitable for various heat treatment furnaces.

Corrosion resistance

Inconel 600 displays excellent corrosion resistance to various corrosive media. The chromium content in the alloy imparts superior corrosion resistance in oxidative conditions compared to pure nickel alloys like Ni-200 and Ni-201 (low carbon). Additionally, its high nickel content provides excellent resistance to corrosion in reducing conditions and alkaline solutions, effectively preventing chloride-iron stress corrosion cracking. Inconel 600 exhibits good corrosion resistance in organic acids such as acetic, formic, and stearic acids, and moderate resistance in inorganic acids. It excels in high-purity water used in primary and secondary cycles of nuclear reactors. Notably, Inconel 600 can resist dry chlorine corrosion, chlorine gas corrosion, and hydrogen chloride corrosion at temperatures up to 650°C. In high-temperature corrosion environments, both annealed and solution-treated alloys maintain good resistance to oxidation and do not exhibit significant scaling in the presence of air. The alloy is also resistant to ammonia and nitriding and carburizing atmospheres. However, in conditions where oxidation media alternate, some corrosion may occur, such as in green death solutions.

Thermocouple protection sheaths in corrosive atmospheres.

Production of vinyl chloride monomers, offering resistance to chlorine gas, hydrogen chloride, oxidation, and carburization.

Fluorine chemical industry for corrosion resistance to hydrofluoric acid.

Manufacturing of corrosive alkali metals, especially in sulfide-rich environments.

Titanium dioxide production using chlorine gas.

Production of organic or inorganic chlorides and fluorides, offering resistance to chlorine gas and fluorine gas corrosion.

Nuclear reactors.

Components in heat treatment furnaces, particularly in carburizing and nitriding atmospheres.

Catalyst regenerators in petrochemical production at temperatures above 700°C for extended service life.

Kiln bottles, parts, vacuum furnace equipment, chlorine equipment with a maximum operating temperature of 1000°F (538°C), titanium dioxide plants, and various heating equipment, distillation towers, condensers, and evaporators in fatty acid processes, evaporator tubes, tube sheets, and pressing plates in sodium sulfide manufacturing processes, and equipment for pitch treatment in pulp manufacturing.

Supply style

Plates, bars, pipes, pipe fittings, fasteners, flanges, etc. can be processed according to drawings, please contact us.

Send Us Your Quotation By Email Can Get A Discount, Contact Us To Get Price List!

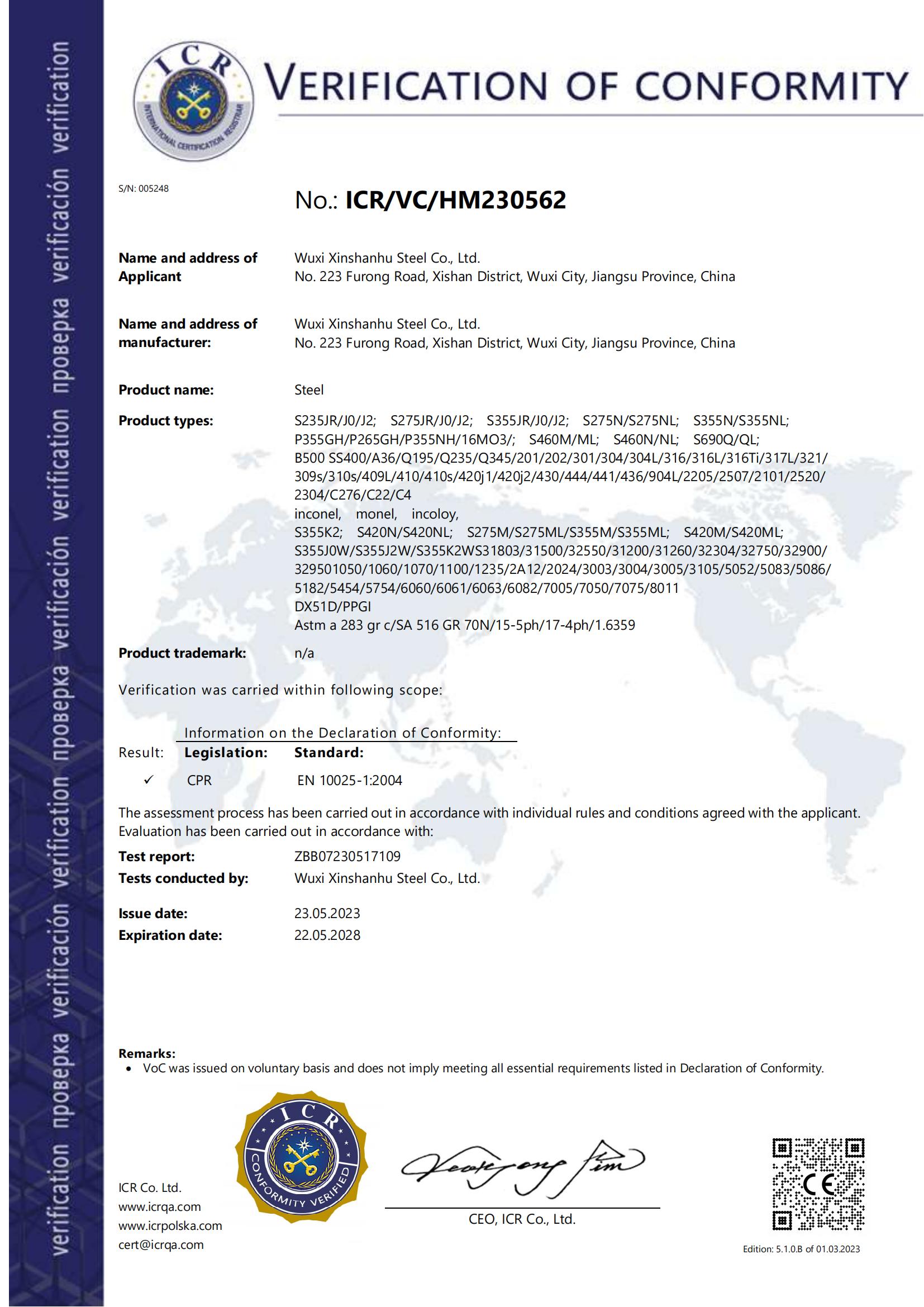

Wuxi Xinshanhu Steel Co., Ltd. is an eleven-year-old Chinese alloy manufacturer with rich production experience, well-trained workers and excellent engineers. Our factory has a mature production system and multiple steel production lines. Including Cold-rolled flat cutting machine, Hot-rolled flat cutting machine; High-speed flat cutting machine; Precision high-speed slitting machine, Ultra high pressure water jet cutting machine; Sheet fiber laser cutting machine; Thin-walled cylinder longitudinal seam automatic welding machine and Machine shop. Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc. The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q1. Where is your factory?

A1: Our company’s processing center is located in Wuxi, Jiangsu, China. It is well equipped with kinds of machines, such as laser cutting machine, mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products?

A2: Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc.The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q3. How do you control quality?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company?

A4: We have many professionals, technical personnel, more competitive prices, and best after-sales service than other alloy companies.

Q5. How many countries have you already exported to?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan, India, etc.

Q6. Do you provide samples? is it free or extra?

A6: Yes, we could offer the sample for free charge but do not pay the cost of freight.