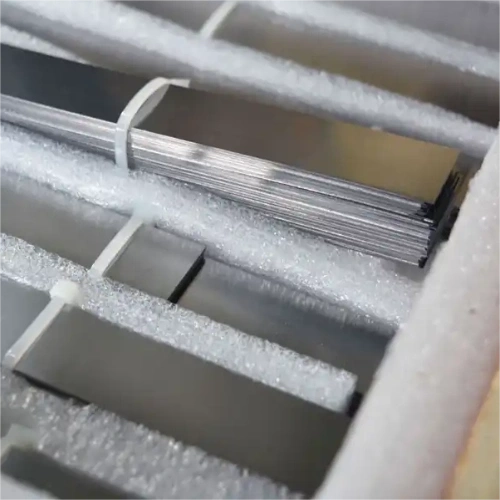

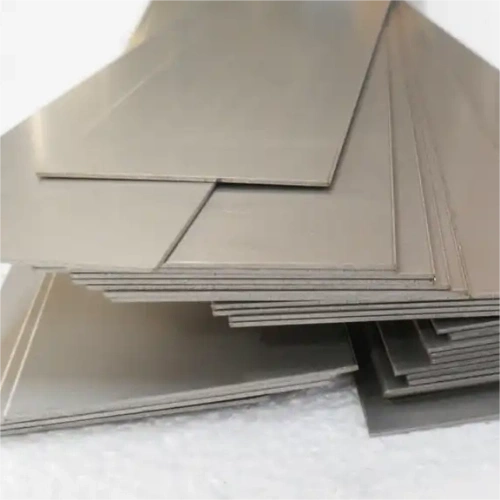

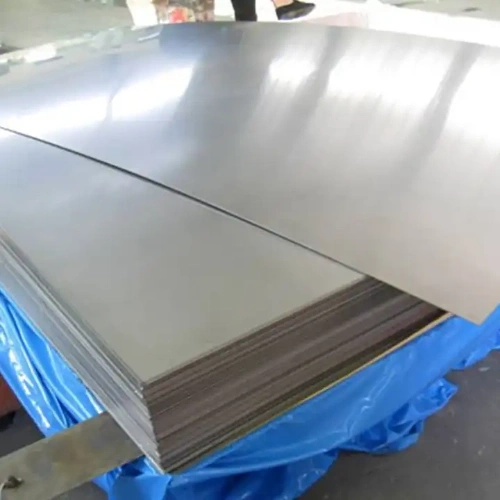

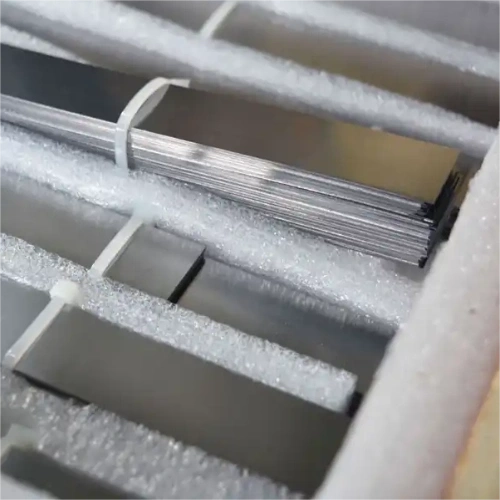

We provide corrosion-resistant alloy plates with thicknesses of 0.3mm-20mm and have a large inventory of cold-rolled plates and hot-rolled plates. We support the sale of single whole plates and customize special shapes or patterns according to customer needs and drawings. Our factory's sheet processing capabilities include shearing, HD plasma cutting and bevel cutting, water jet cutting and laser cutting (thin sheet), guaranteeing the possibility of realizing square, rectangular, round, ring and strip or custom shaped sheets.

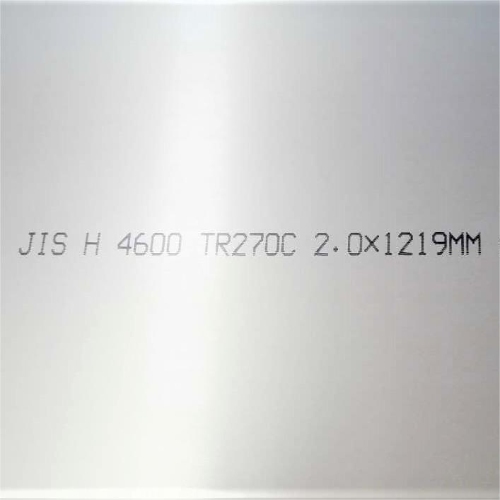

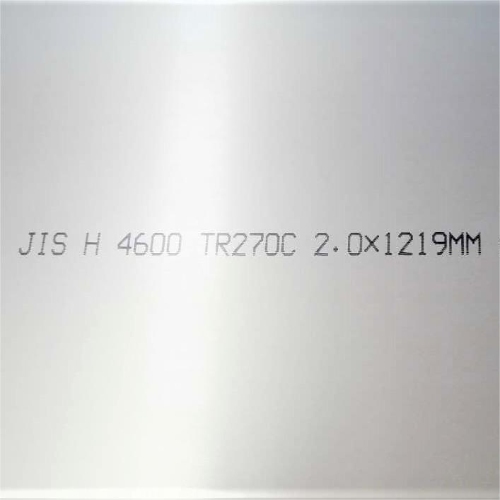

Titanium alloy GR.1 (also called pure titanium GR1, TR270C, ASTMB265). Titanium has strong corrosion resistance in many media, especially in neutral and oxidizing media. It can also be used in some dilute reducing acids, such as various acids from normal temperature to boiling point. concentration of nitric acid. It has good corrosion resistance to most alkali solutions, such as saturated solutions of barium hydroxide, calcium hydroxide, and magnesium hydroxide at room temperature, but it cannot be used for boiling sodium hydroxide solutions. Titanium is not corroded at all in seawater and is also resistant to corrosion in most organic acids (except formic acid and oxalic acid). It has excellent corrosion resistance in wet chlorine gas and chloride solutions such as chlorite and hypochlorite. Corrosion resistance in sodium chloride solutions increases with increasing solution pH. The disadvantage is that it will fail quickly in an environment containing fluoride and hydrofluoric acid corrosion.

Titanium's thermal expansion coefficient is small, making it less thermal stress generated under high-temperature working conditions or during thermal processing. The thermal conductivity of titanium is poor, only 1/5 of iron. In addition, the friction coefficient of titanium is large (μ=0.2), making cutting and grinding difficult. Titanium has a low elastic modulus and a high yield-to-strength ratio, which makes titanium and titanium alloys have a large amount of rebound during cold deformation and are difficult to form and straighten..

Corrosion resistance

Titanium has excellent corrosion resistance in alkaline solutions such as sulfuric acid, hydrochloric acid, nitric acid, and sodium hydroxide, as well as in moisture and seawater. But titanium is not resistant to the etching effect of hydrofluoric acid. Titanium is very stable in the atmosphere. A dense oxide film is formed on the surface, which can maintain the metallic luster. However, when heated to above 600°C, the oxide film loses its protective effect.

Aerospace, plate heat exchangers, bellows compensation expansion joints, seawater desalination, desulfurization and denitrification, chemical equipment civil tableware industries, etc.

Supply style

Plates, bars, pipes, pipe fittings, fasteners, flanges, etc. can be processed according to drawings, please contact us.

Send Us Your Quotation By Email Can Get A Discount, Contact Us To Get Price List!

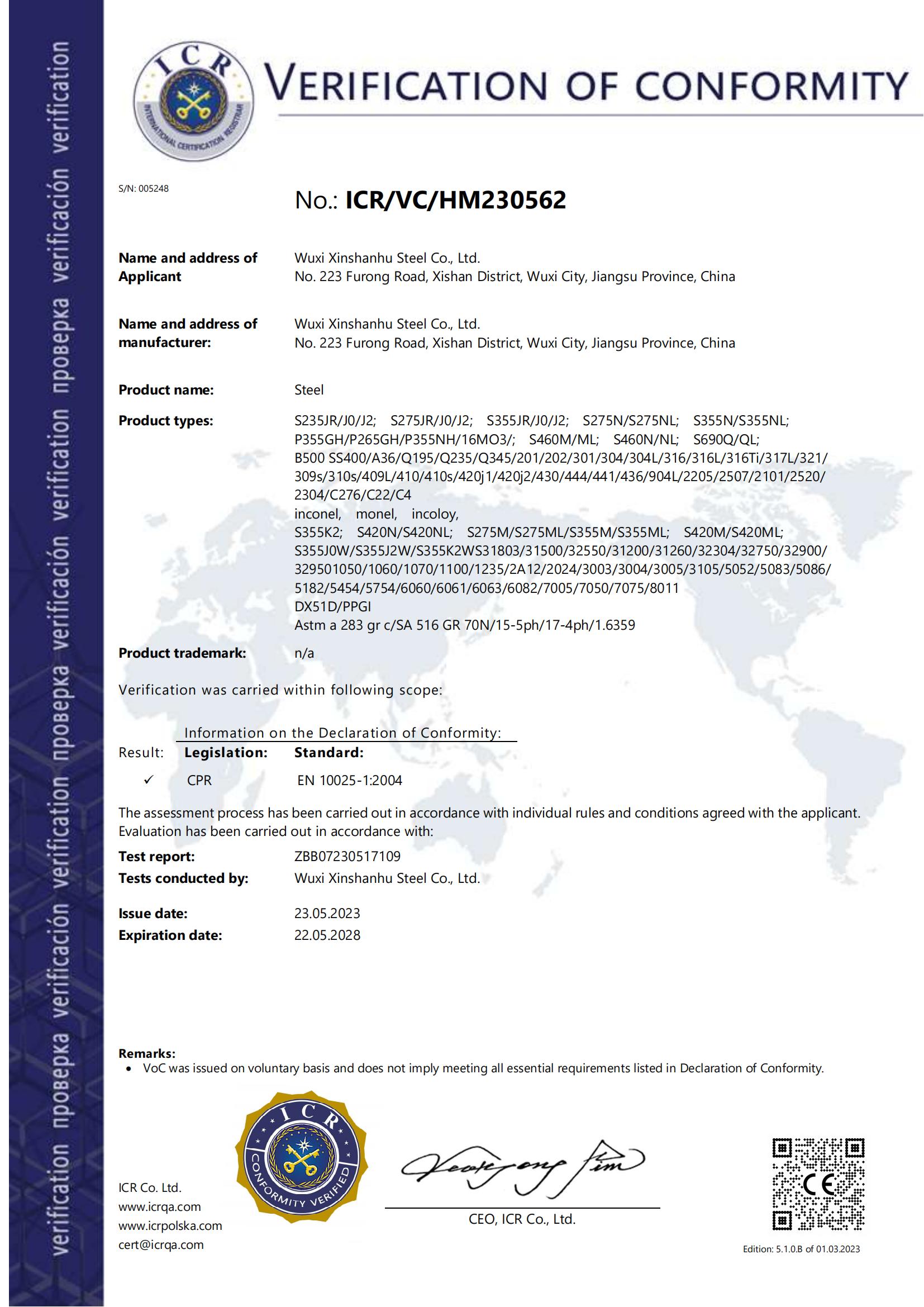

Wuxi Xinshanhu Steel Co., Ltd. is an eleven-year-old Chinese alloy manufacturer with rich production experience, well-trained workers and excellent engineers. Our factory has a mature production system and multiple steel production lines. Including Cold-rolled flat cutting machine, Hot-rolled flat cutting machine; High-speed flat cutting machine; Precision high-speed slitting machine, Ultra high pressure water jet cutting machine; Sheet fiber laser cutting machine; Thin-walled cylinder longitudinal seam automatic welding machine and Machine shop. Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc. The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q1. Where is your factory?

A1: Our company’s processing center is located in Wuxi, Jiangsu, China. It is well equipped with kinds of machines, such as laser cutting machine, mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products?

A2: Our products include Hastelloy, Incoloy, Inconel, Monel, Nickel Alloy, Nickel Alloy, Titanium Alloy, Haynes, etc.The supply styles include plates, strips, rods, wires, forgings, bare rods, welding materials, flanges, etc. We support custom-made according to drawings.

Q3. How do you control quality?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company?

A4: We have many professionals, technical personnel, more competitive prices, and best after-sales service than other alloy companies.

Q5. How many countries have you already exported to?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan, India, etc.

Q6. Do you provide samples? is it free or extra?

A6: Yes, we could offer the sample for free charge but do not pay the cost of freight.