Hastelloy C-22 is mainly composed of elements such as nickel (Ni), molybdenum (Mo), chromium (Cr) and iron (Fe). It is a high-performance nickel-based alloy with excellent corrosion resistance and thermal stability. , is an alloy widely used in the chemical industry.

Hastelloy C-22 is known for its excellent corrosion resistance. It is resistant to a variety of strong acids, alkalis and oxidizing media, including sulfuric acid, hydrochloric acid, chlorine and hydrofluoric acid. This makes Hastelloy C-22 the material of choice for handling corrosive materials.

Hastelloy C-22 offers superior performance over a wide temperature range. It can maintain its strength and corrosion resistance at extremely low temperatures and is also suitable for high-temperature environments, so it is widely used in high-temperature and high-pressure equipment in the chemical industry.

Hastelloy C-22 has good oxidation resistance, which makes it less prone to oxidation and corrosion at high temperatures, thereby extending the service life of the material.

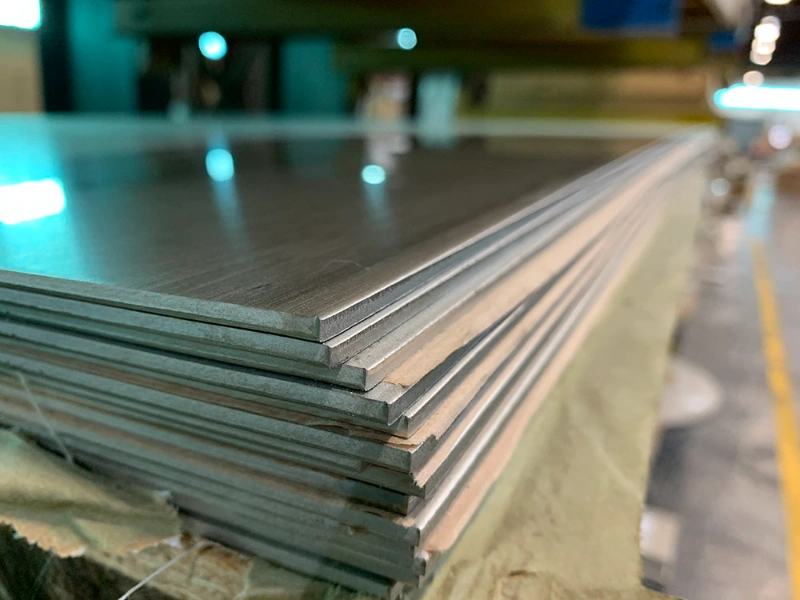

Hastelloy C-22 can be rolled, welded and machined, giving it excellent processability during manufacturing and installation.

Hastelloy C-22 is widely used in the chemical industry, including pharmaceuticals, fertilizers, pickling, wastewater treatment and other fields. It is often used to manufacture reactors, pipelines, pumps, steam traps and other equipment to resist corrosion and high-temperature environment erosion. High Purity Requirements: In some applications, Hastelloy C-22 needs to be of high purity to meet the extreme purity and chemical stability requirements for the material.

In summary, Hastelloy C-22 is a very important engineering alloy that is widely used for its excellent corrosion resistance and thermal stability. When handling highly corrosive chemicals and in high temperature, high pressure environments, Hastelloy C-22 is a reliable choice to ensure long-term equipment reliability and performance.